-

Email : xinzino70@gmail.com

Email : xinzino70@gmail.com

Development of proton exchange membrane (PEM) electrolysis systems based on electrochemical technology

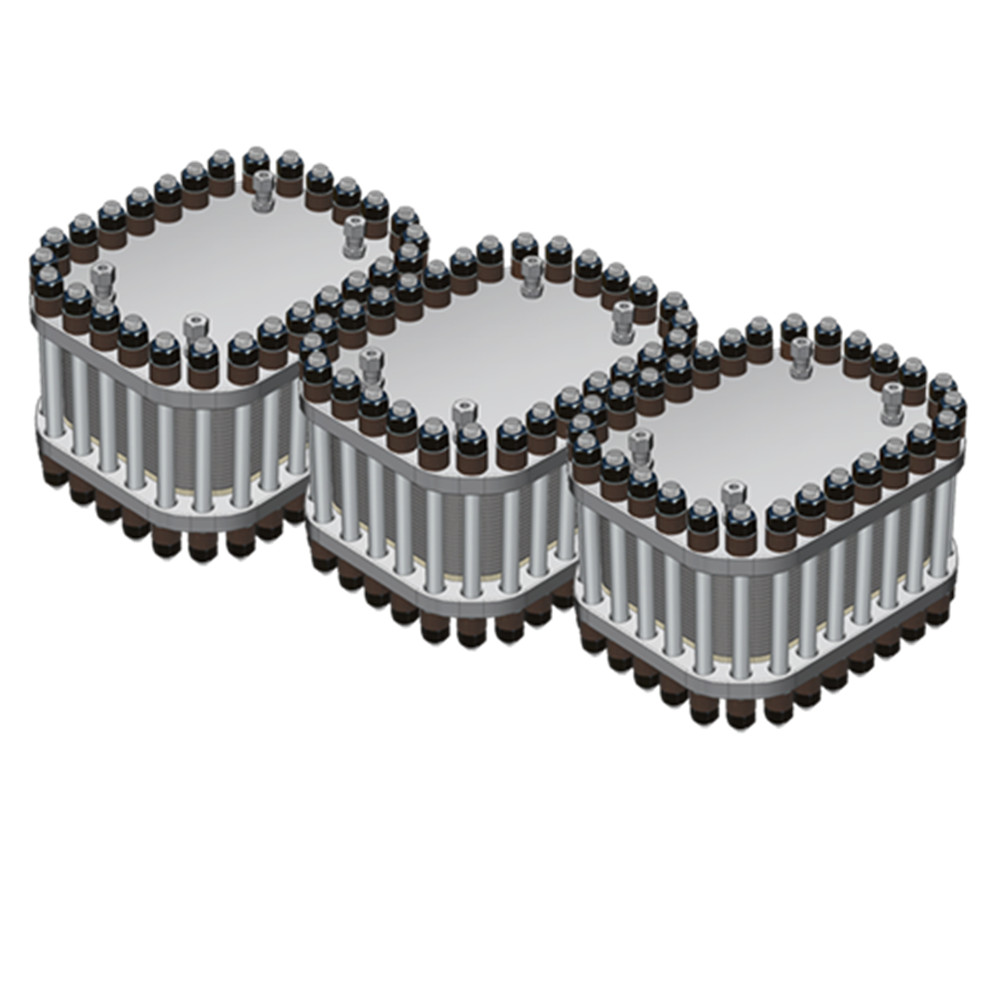

Focus on developing and manufacturing large modular electrolyzer stacks and systems

Technological excellence

The technical advantages of our PEM systems

Differential pressure design (O2 < 1 bar, H2 up to 30barg) -> no risk of oxygen contamination

Negligible amount of H2 in the system

No harmful chemicals used (no KOH)

unique purging process without risk of gas mixing

Extremely easy to maintain extremely reliable and safe

Specifications / Key Features

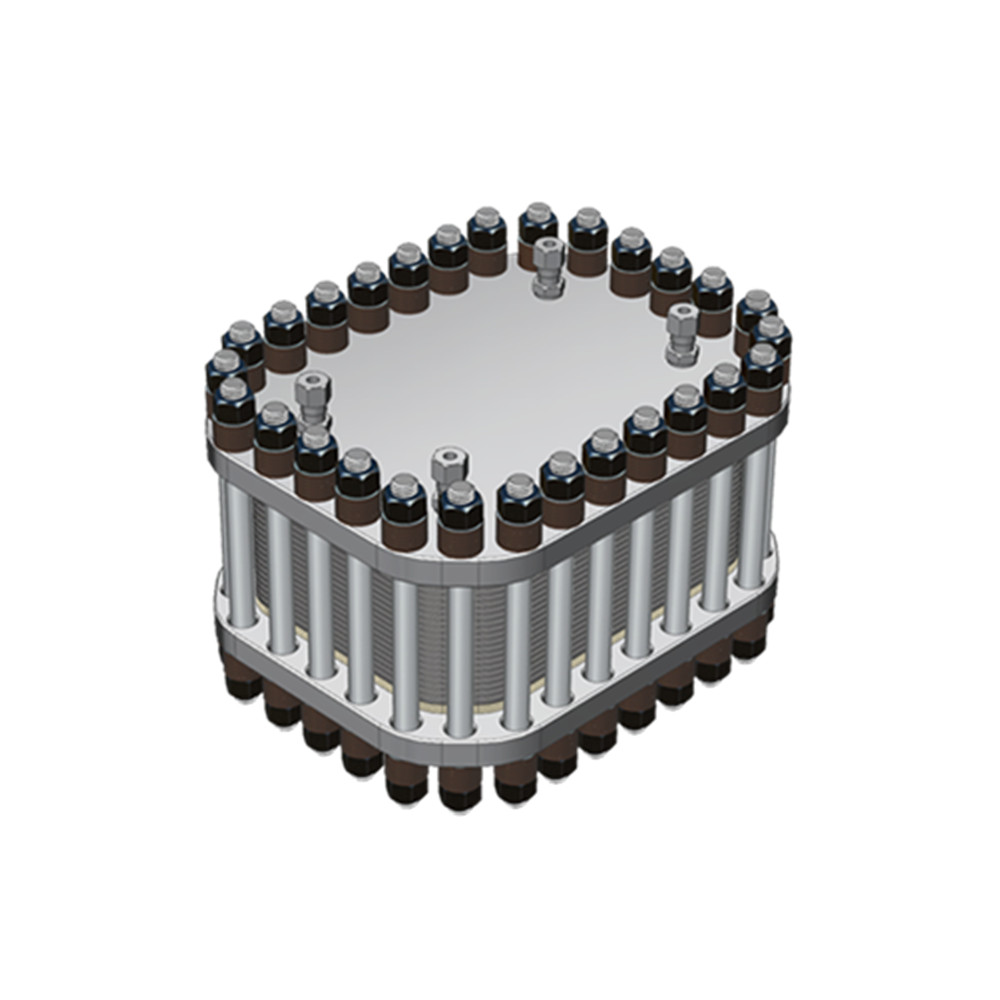

Electrolyser technology: PEM

Stacks: 1

Productivity: 2000 NL/h, 4.315 kg/24h

Hydrogen purity: 99.99% (or>99.999%)

Outlet pressure (barg): 35

Per Nm ³ Nominal power consumption of H2 generated: 4.5 kWh/Nm ³

Operating ambient temperature range: 60 ° C

Water specification: 1 µS/cm (at 25 ° C)

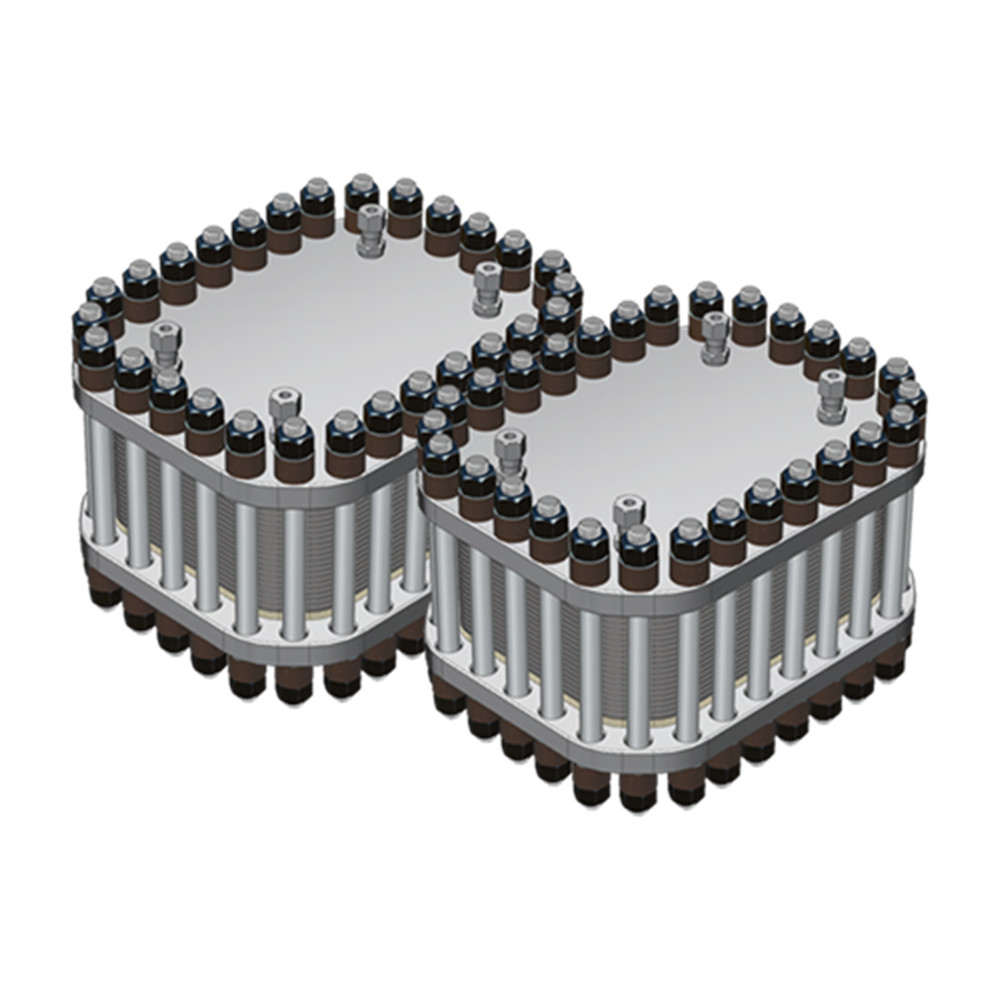

Electrolyser technology:PEM

Number of stacks:2

Production Rate:Up to 4000 NL/h, up to 8.63 kg/24h

Hydrogen Purity:99.99% (or > 99.999% )

Outlet Pressure (barg):35

Nominal power consumption per Nm³ of H₂ produced:4.5 kWh/Nm³

Ambient operative temperature range:60°C

Water Specification:1µS/cm (at 25°C)

Electrolyser technology:PEM

Number of stacks:3

Production Rate:Up to 6000 NL/h, up to 10.071kg/24h

Hydrogen Purity:99.99% (or > 99.999% )

Outlet Pressure (barg):35

Nominal power consumption per Nm³ of H₂ produced:4.5 kWh/Nm³

Ambient operative temperature range:60°C

Water Specification:1µS/cm (at 25°C)

Customised PEM electrolyser specifications to suit customer requirements

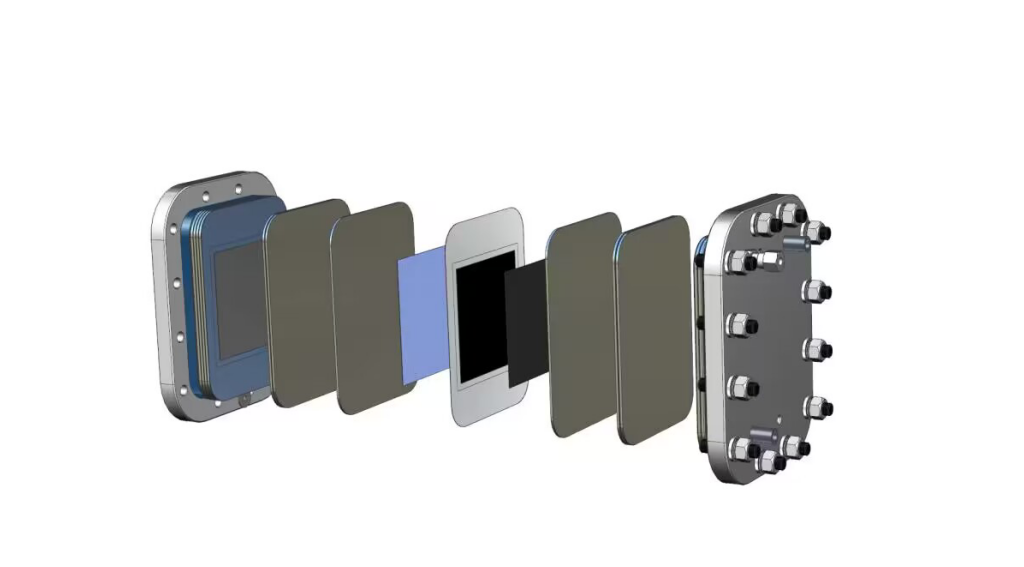

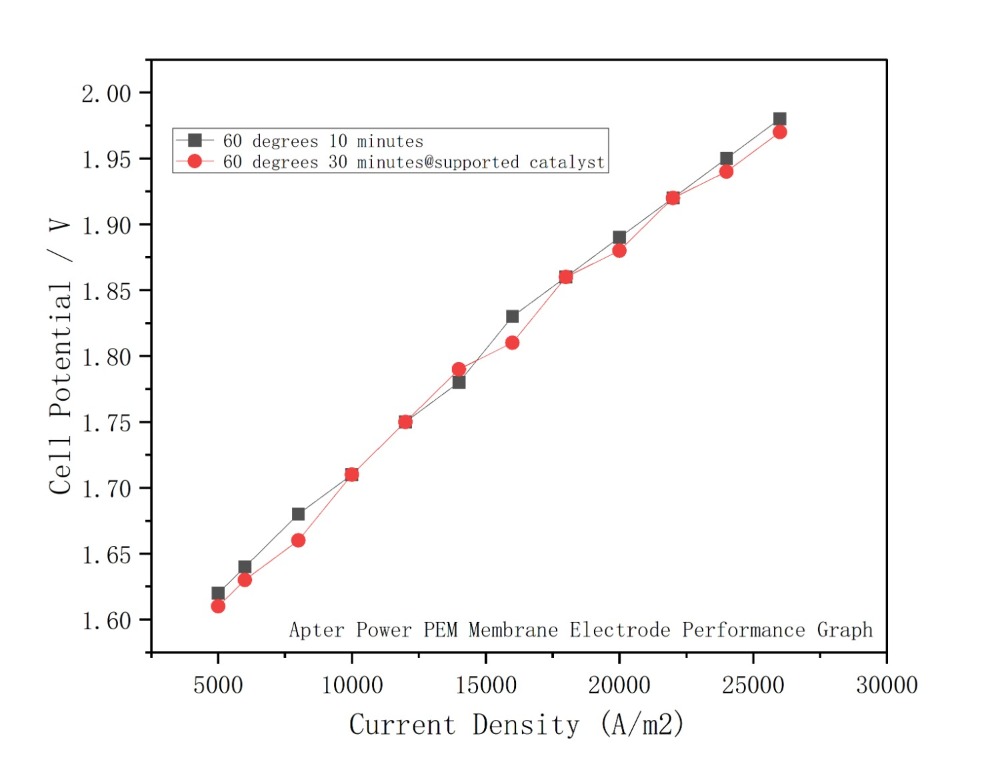

We design and manufacture high performance catalyst coated membranes (CCM), the heart of our Proton Exchange Membrane (PEM) electrolysers.

MEMENERGYLLC(PEM) electrolyzers are designed for safe, simple, low-maintenance operation without processing harmful substances.

Hydrogen widely used in various chemical and physical processes and MEMENERGYLLC is committed to serving a variety of applications with our reliable hydrogen generators.